Real-Time Temperature and Humidity Data Logger: The Key to Pharmaceutical Storage Security

In the pharmaceutical industry, the storage of drugs is a critical component in ensuring their quality and safety. As such, real-time temperature and humidity data recorders have emerged as an indispensable tool for pharmaceutical companies.

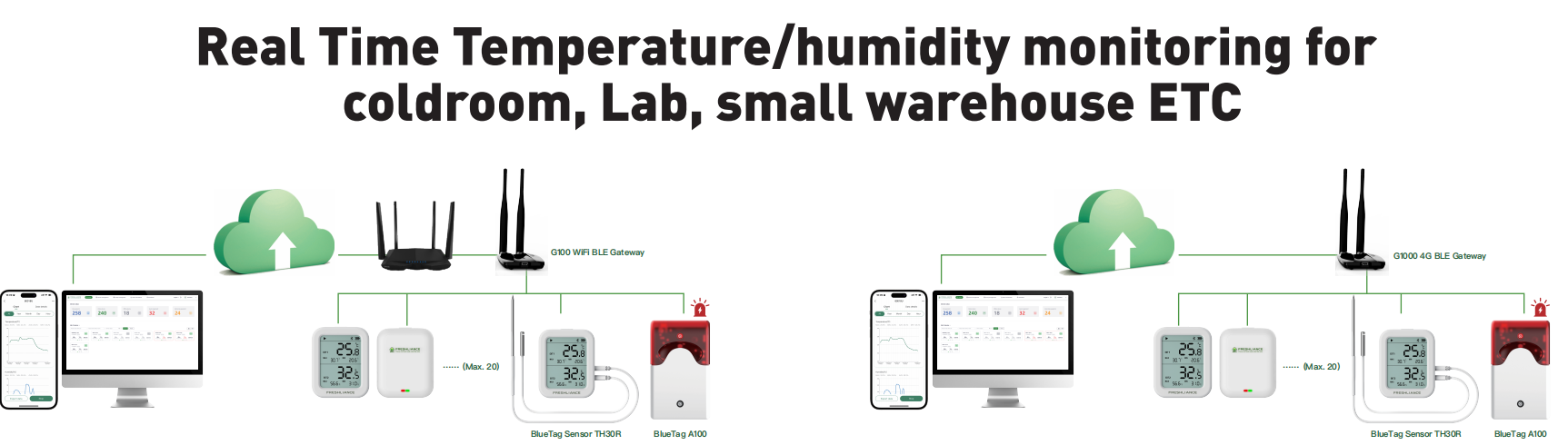

By providing precise and continuous monitoring of temperature and humidity, these data loggers offer an efficient means of safeguarding drug storage. With each drug having specific temperature and humidity requirements, any deviation from these conditions could result in a decline in drug efficacy, or worse, drug failure.

Through real-time monitoring, staff can obtain temperature and humidity data for various areas within the warehouse, and receive immediate notifications when an abnormality occurs. The data recorder acts like a pair of sharp "eyes," continuously ensuring the safety of the drugs.

For example, imagine a cold storage area in a large pharmaceutical factory with a batch of new anti-cancer drugs that are about to hit the market. Thanks to real-time temperature and humidity data loggers, any minor faults in the refrigeration system can be detected immediately, averting a potential deterioration of drugs due to temperature rise.

Moreover, the data recorded by these recorders also holds important traceability value. By reviewing historical temperature and humidity data, any disputes over drug quality can be resolved quickly and effectively, improving storage processes to mitigate future issues.

In conclusion, real-time temperature and humidity data loggers are paramount in the pharmaceutical industry's storage process, and serve as an important safeguard in maintaining both drug quality and patient health.