Application of Bluetooth Temperature and Humidity Data Logger for Cold Room

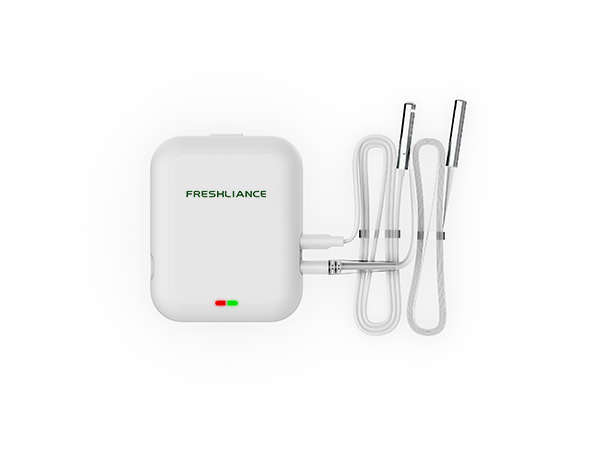

Cold rooms are commonly applied in many industries for cold chain storage and warehouse of their sensitive products. To better control the environmental data of the cold rooms, our BlueTag TH30R will be a good option. BlueTag TH30R is a Bluetooth temperature and humidity data logger coming with external probes, ideal for cold rooms. Besides, it brings many other benefits.

Temperature and Humidity Monitoring

Continuous Monitoring: Freshliance BlueTag TH30R temperature and humidity data logger provides continuous monitoring of temperature and humidity levels within the cold room. This allows for immediate detection of any fluctuations or deviations from the desired set points. For example, in a food storage cold room, maintaining a specific temperature range is crucial to prevent spoilage. If the temperature rises even slightly above the recommended level, it could accelerate the growth of microorganisms and reduce the shelf life of perishable items.

Accurate Measurements: The data logger offers highly accurate temperature and humidity readings, ensuring that the actual conditions within the cold room are precisely known. This is essential for industries such as pharmaceuticals, where precise temperature control is necessary to maintain the efficacy and stability of drugs. Even a small error in temperature measurement could potentially compromise the quality of sensitive medications.

Quality Control and Assurance

Product Integrity: By closely monitoring temperature and humidity, it helps ensure the integrity of products stored in the cold room. In the case of fresh produce, maintaining the right humidity level is as important as temperature control. If the humidity is too low, fruits and vegetables may lose moisture and shrivel, affecting their appearance and quality. On the other hand, excessive humidity can lead to mold growth. The data logger enables early intervention to prevent such issues and maintain product quality.

Compliance with Standards: Many industries have strict regulatory requirements regarding temperature and humidity control in cold storage. For instance, the food and beverage industry must adhere to food safety standards that specify precise temperature ranges for different types of products. The data logger provides the necessary documentation to demonstrate compliance with these standards, which is crucial during audits and inspections.

Energy Management

Optimizing Cooling Systems: By analyzing the real-time temperature and humidity data, it becomes possible to optimize the operation of the cold room's cooling system. For example, if the data shows that the temperature remains stable within the desired range for extended periods, the cooling system's settings can be adjusted to reduce energy consumption without sacrificing product quality. This can result in significant cost savings over time, especially for large-scale cold storage facilities.

Identifying Inefficiencies: The data logger can also help identify areas of inefficiency in the cold room's insulation or cooling system. If there are sudden drops or spikes in temperature that cannot be attributed to normal usage patterns, it may indicate a problem with the insulation or the cooling equipment. Early detection of such issues allows for timely repairs or upgrades, preventing further energy wastage and potential product damage.

Alarm and Alert Systems

Immediate Notification: The data logger can be configured to send out alarms or alerts when temperature or humidity levels exceed predefined thresholds. This ensures that personnel are immediately notified of any critical changes in the cold room environment, enabling them to take prompt corrective action. In a hospital pharmacy cold room, for example, an alarm would sound if the temperature deviated from the required range for storing vaccines, allowing staff to transfer the vaccines to a backup storage unit or address the issue quickly to avoid spoilage.

Remote Monitoring: With the ability to connect to a network, the data logger enables remote monitoring of the cold room's conditions. This means that supervisors or technicians can receive alerts on their mobile devices or computers, even when they are not physically present at the facility. This remote access feature enhances the overall management and control of the cold room, especially for multiple-site operations or during off-hours.

Data Logging and Analysis

Historical Records: The data logger stores historical temperature and humidity data, creating a comprehensive record of the cold room's environmental conditions over time. This data can be used for trend analysis, helping to identify seasonal variations, usage patterns, or any long-term changes in the cold room's performance. For example, by analyzing past data, it may be possible to predict when the cooling system is likely to experience higher demand and schedule preventive maintenance accordingly.

Process Improvement: The detailed data provided by the logger can also be used to evaluate and improve existing cold room management processes. If the data shows that certain loading or unloading procedures consistently cause temperature fluctuations, adjustments can be made to these processes to minimize their impact. Additionally, the data can be used to optimize inventory management by understanding how different products respond to temperature and humidity changes during storage.